So that we could improve general preparedness and be more comfortable during power outages, I decided it was time to buy or potentially put together a portable power station like is so popular for camping/outdoors and emergencies these days (such as from Jackery or Goal Zero; see portable power stations at REI). They are also awkwardly called "solar generators" because they can be charged with solar panels, even though they are really just batteries with some outputs. I suppose the solar panel is the true generator.

I realized this was actually a perfect opportunity for DIY: commercial systems are quite expensive, and DIY would be achievable since the components are so modular. Can be as simple as battery, inverter, and charger. Let's do it!

|

| Completed solar generator power station in a milk crate. Battery, charge controller, inverter, charger, 12V outputs, USB ports, and zippered pouches for cables and accessories |

In my early research I also realized that adding solar charging is almost trivial—requires only a solar charge controller and then whatever panels I want. In a bit of impulsiveness, I bought the 100W solar kit from Harbor Freight. I wouldn't do it again, but more about that later. I've since learned that many higher quality kits are available, even at a lower cost.

Power Station Build—Parts and Design

I decided to build the system simply in a milk crate that I already had, partly inspired by this video by Will Prowse (I highly recommend all his videos), which also shows a lot of construction techniques. Lots of people online built out toolboxes and even ammo cans, but my system is intended to mostly stay home for emergencies and tinkering. A milk crate allows for lots of modularity and airflow.

|

| Solar generator / power station block diagram |

Key components

(note that these are affiliate links and I will earn a commission if you make a purchase; thanks!)

- Battery - 12V 100Ah Weize AGM

- 1200W inverter (modified sine wave)

- Also check out the pure sine version, 1000W

- There are tons of different versions available to suit your needs

- Solar starter kit (Harbor Freight)

- I wouldn't really recommend this one though, unless you specifically want the included accessories; see notes below

- A higher quality and cheaper alternative from Renogy

- Noco Genius 10 smart charger

- Can also get away with just a bench power supply—I love this one. But then the system isn't quite as robust and easy to use.

- DROK Current meter

- I found that the current reading is 20% off, but it serves its purpose. Maybe there is a better one?

- Car outlet 14awg 20A

- USB-C 12V car charger

Smaller bits and tools

- XT60 connectors with pigtails

- These handle high current and are cheap and easy to work with; big win

- Crimp terminals

- Fuse block

- Blade fuses (assortment)

- Milk crate (12"x18" inside dims)

- Probably cheapest to find locally; I already had one

- 10awg parallel two-conductor silicone wire

- 12awg parallel two-conductor silicone wire

- 14awg parallel two-conductor silicone wire

- 6awg welding cable for inverter

- Can also just get pre-made cables

- Do not buy "copper clad aluminum" (CCA) wire. It is cheaper for the same gauge, but does not carry as much current, and being dissimilar from copper will cause problems with crimp connections over time (thermal expansion, corrosion).

- Inverter cable crimp tool

- Inverter cable lugs with heat shrink

- Excellent wire gauge calculator and high-quality marine wire source

Results and Features

- In/Out

- 2x 120Vac outlets

- 4x USB charge ports

- 2x high current XT60 connectors

- 2x cigarette lighter sockets

- 3x 5.5x2.1mm DC outlets

- Capacity

- 12V 100Ah AGM lead acid battery with about 600-900Wh of usable capacity (1200Wh in an emergency)

- Since I’m not cycling the system daily, I don’t mind to do an occasional deep discharge of the battery (~80% or even higher), since there would probably be a good reason for it. (For longest life, the rule of thumb is to limit to 50% depth of discharge)

- Charging

- Solar input

- Solar charge controller also accepts input besides solar panels -- see below

- AC wall charger

- Monitoring

- Coulomb counting meter and voltage display

- Performance

- No problem to run the inverter at the rated 1200W for at least 30 minutes (this equates to about 50% of the battery used at 100A)

Notes on the Harbor Freight solar starter kit

I can't really recommend this kit. The 4x 25W panels add up to a size much larger than a standalone 100W panel, and the plastic frames make them feel much more flimsy and awkward to mount. I don't like that it uses SAE connectors which are just a disaster in terms of managing polarity. And the controller is very poorly documented. The kit from Renogy, for example, includes longer and higher-gauge cables and uses solar panel standard MC4 connectors. Plus the single panel has an aluminum frame. The kit from Weize is similar and even cheaper.

Some notes on the specs:

- The charge controller is 10A PWM which will work with 100-200W of panels

- (The box shows the option of wiring up 400W of panels through a hub, but this would require a 30A controller which they sell separately)

- The load ports have short circuit and overcurrent protection. I was able to draw 7.5A continuously, and it shut off at 8A.

- The load output has a timer, but I could not get it to work reliably

Some Interesting things I learned

XT60 and other connector gender

For electrical connectors, the convention is that power sources such as batteries use a female connector. This is safer since it's harder to accidentally touch the conductors, and it is also harder to short out a connector with a stray wire since the conductors are usually recessed.

|

| XT60 connectors female (left) and male (right) |

For XT60 connectors, the male connector (with the pins) has a body that goes outside of the female connector, leading to come confusion. But it is definitely the case that the connector with the pins is male, and the electrical sockets is female. The manufacturer even labels them as such.

Hooking up a power supply to a solar charge controller

It's not only solar panels that can be used to charge the battery with a PWM solar charge controller! Any power supply will do, as long as the output voltage is higher than your battery and it has a "constant current" function to limit the current flow. Most normal power supplies, like an old laptop power supply you can probably find for free, do not have this feature and will just shut down due to overcurrent when hooked up to charge a battery.

You can add the constant current feature with a buck converter (like this one) in between the power supply and battery. Then a 19.5V laptop power supply (for example) will be brought down to the ~12V of the battery in a controlled fashion, with a constant current that can be set to match the ability of the power supply.

AGM battery state of charge monitoring

The voltage of a battery can be used to estimate its state of charge, but it's really only a vague estimate, especially in the case of lead acid. Counting how much current has been used since being fully charged is the real way to keep track, and that's how your phone, etc., can report its charge as a percentage. Here is an awesome resource on AGM battery state of charge, plus info about charging stages from the same site. And more on charging lead acid batteries in general.

Solar panel I/V curve and MPPT

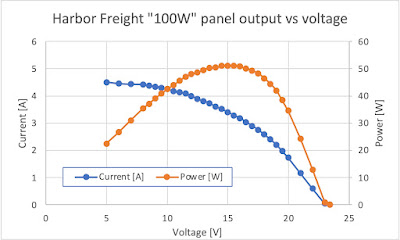

MPPT (Maximum Power Point Tracking) is a feature of some solar charge controllers that allows them to draw power at a voltage the corresponds to the maximum power of the solar panel. This video from TU Delft explains more. Every panel has a V/I curve, and somewhere on it will be maximum power. Example plot:

|

| Example theoretical solar panel V-I plot. Isc = short circuit current. Ipmax = current at max power. Pmax = max power. Vpmax = voltage at max power. Voc = open circuit voltage. |

I collected this data for the Harbor Freight panels using a DC load in the constant voltage mode:

|

| Measured V-I curve for solar panel set |

Even though it was sunny at the time, it did not approach 100W. Maybe it will do better in the summer but chances are these are just kinda crummy panels. Peak power comes at about 16V, so theoretically that's where an MPPT charge controller would operate. But down at battery voltages (12-14V) the panel still generates 95% of the peak power, so these panels are well suited for a PWM charge controller and 12V battery.

|

| Using a DC load in constant-voltage mode to measure the power characteristics of the solar panel. My assistant loves this thing. |

Conclusions and future options

This was a successful project—not only was it an incredible learning experience of battery systems and solar power, but it works as intended to fulfill a useful function. Total cost to me was $644, which is more than I expected, but that includes the price of some of the things I already had. For comparison, a Jackery 1000 which would have similar features and emergency capacity costs $1099, and that's before adding solar panels!

In a future system, I will probably build a battery with Lithium Ion 18650 cells since they can be found cheap/free recycled, are much lighter and more compact than lead acid, and I don't need as long a cycle life as is available with newer LiFePo4 battery systems.

Have you built a system like this? How did it go? Let me know in comments below!

Cheers,

Mike

|

| Early test of the solar generator system with solar panels |

Great

ReplyDeleteThat's great information, thanks a bunch..

ReplyDelete