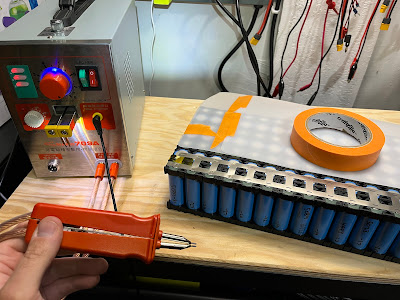

Finally all the pieces are coming together! With my DIY 24V lithium-ion battery complete, it’s time to put it all together into a new portable solar power station and retire my original one. The original power station used a lead-acid AGM battery (60lbs alone), so was not very portable. This new one is more than double the capacity, less than half the weight, and cleanly packaged.

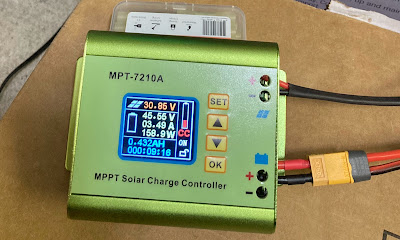

The goal for this project is to make a battery station that is always active and collecting power from my solar panels. This means the DIY powerwall can stay dormant most of the time for maximum safety. Once the solar battery fills up, I can dump it into the powerwall all at once with a boost converter (to go from 24V to 48V), or at any time use it to charge up my ebikes (generally also with a boost converter).

|

| The business inside! Solar charge controller, fuse block, and power input/output ports. More details below |